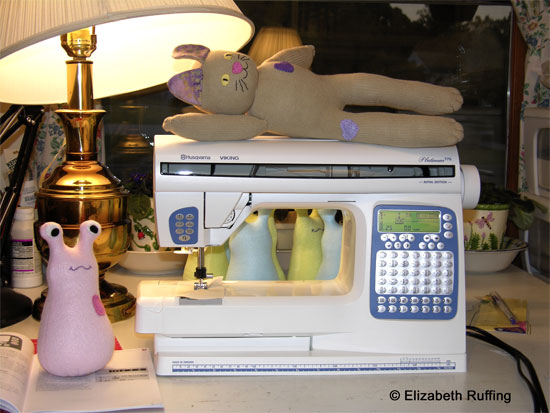

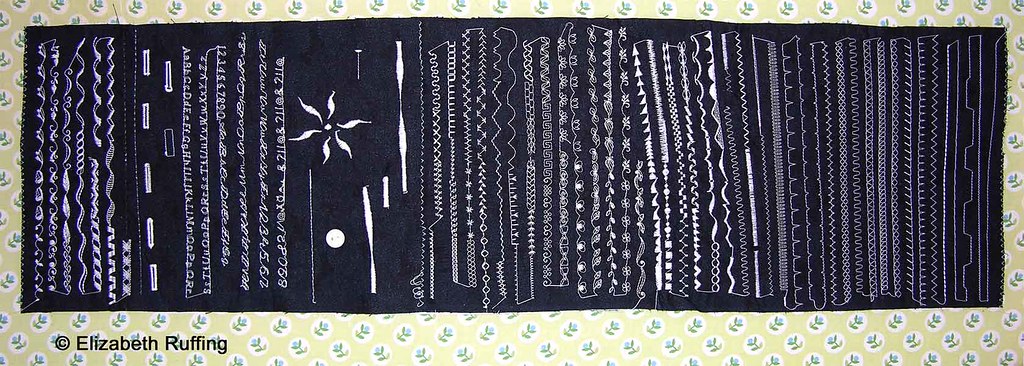

Click on this photo and you’ll get an idea of just how many stitch functions I tested on my new sewing machine. There are a three different stitch types per row on parts of my sewing sample. I read my manuals a couple of times each before I sewed. The machine beeps when you do something wrong, which helps you learn, like negative reinforcement. I was happy that it only beeped a few times. When I first tried it, it was beeping a lot. That’s why I read the manuals more than once! Anyway, it works great. I’ve calmed way down about using it now.

Click on this photo and you’ll get an idea of just how many stitch functions I tested on my new sewing machine. There are a three different stitch types per row on parts of my sewing sample. I read my manuals a couple of times each before I sewed. The machine beeps when you do something wrong, which helps you learn, like negative reinforcement. I was happy that it only beeped a few times. When I first tried it, it was beeping a lot. That’s why I read the manuals more than once! Anyway, it works great. I’ve calmed way down about using it now.

One of my missions tomorrow is to renew my library card. I’d like to read some novels for a change. For the past two or three (or four) years, it seems, I have been reading text books and manuals almost exclusively. I let my library card lapse because those sorts of books are best when they are most current. Anything that new at the library is always out on loan. I am tired of the hype on TV and the Internet, and fiction is a good distraction. Reading absorbs a lot of thought and anxieties. I almost think avoiding reading novels is good sometimes because I find I have more creative ideas without any additional distractions, but right now, I have so much “mental clutter”, that I think I need something just to distract me from my own distractions!

Oh, and I sort of made myself get dressed up when I went out on Friday night. Sort of. I felt like I had forgotten how to dress myself! It was funny, like your first day of high school when you were completely unsure of what went with what. I felt like that. I guess it’s just been too long! Later that night, I was watching two ladies in their sixties out on the dance floor, keeping up with all the younger people there, even when the music got more and more modern, and I still had that feeling. There was a time, I know, when I felt more self-assured, when I knew what to wear, and when I’d go dance too, but, lately, I feel like it’s my first day of high school. I’m sure it will pass.